With our know-how and many years of experience, we have developed a procedure to process ceramics and plastics in such a way that they can be used for many applications, thus replacing expensive metal tools. The tools can be manufactured inexpensively and very quickly. For prototypes and small and large series, our tools are a good alternative to metal tools. Thanks to the heated moulds and/or negatives, interesting products are created using pressing, casting, injection, or reshaping!

Possible fields of application:

- Pre-shaping of fibre composites

- Serial production of laminates with vacuum injection

- Casting of prototypes and small series

- Injection procedure for small and large series

- Prepreg (fibre composites) up to about 150 °C in simple tool geometries, for prototypes and small and large series

- Investment casting using the lost wax method for prototypes and small series

- Glass parts using casting, blowing, or reshaping

Advantages over metal moulds:

- Simple and fast manufacturing method

- Cost savings of 20-60% or more compared to conventional metal tools

- Inexpensive and rapid modifications using plastic negatives / original models possible

- Low thermal expansion of the negatives

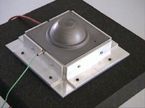

- Integrated electric heating system (user-friendly, clear and simple)

- No soiling due to oil

- Monitoring of the mould surface temperature to control the supply of electrical power

- Time savings in processing the tool

- Relatively little effort for ornamental work of plastic negatives and/or original models